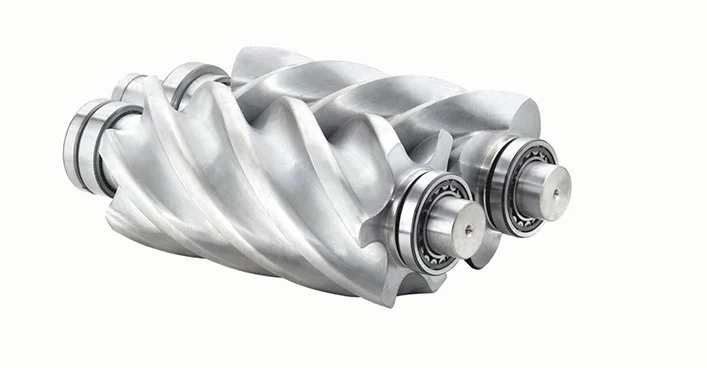

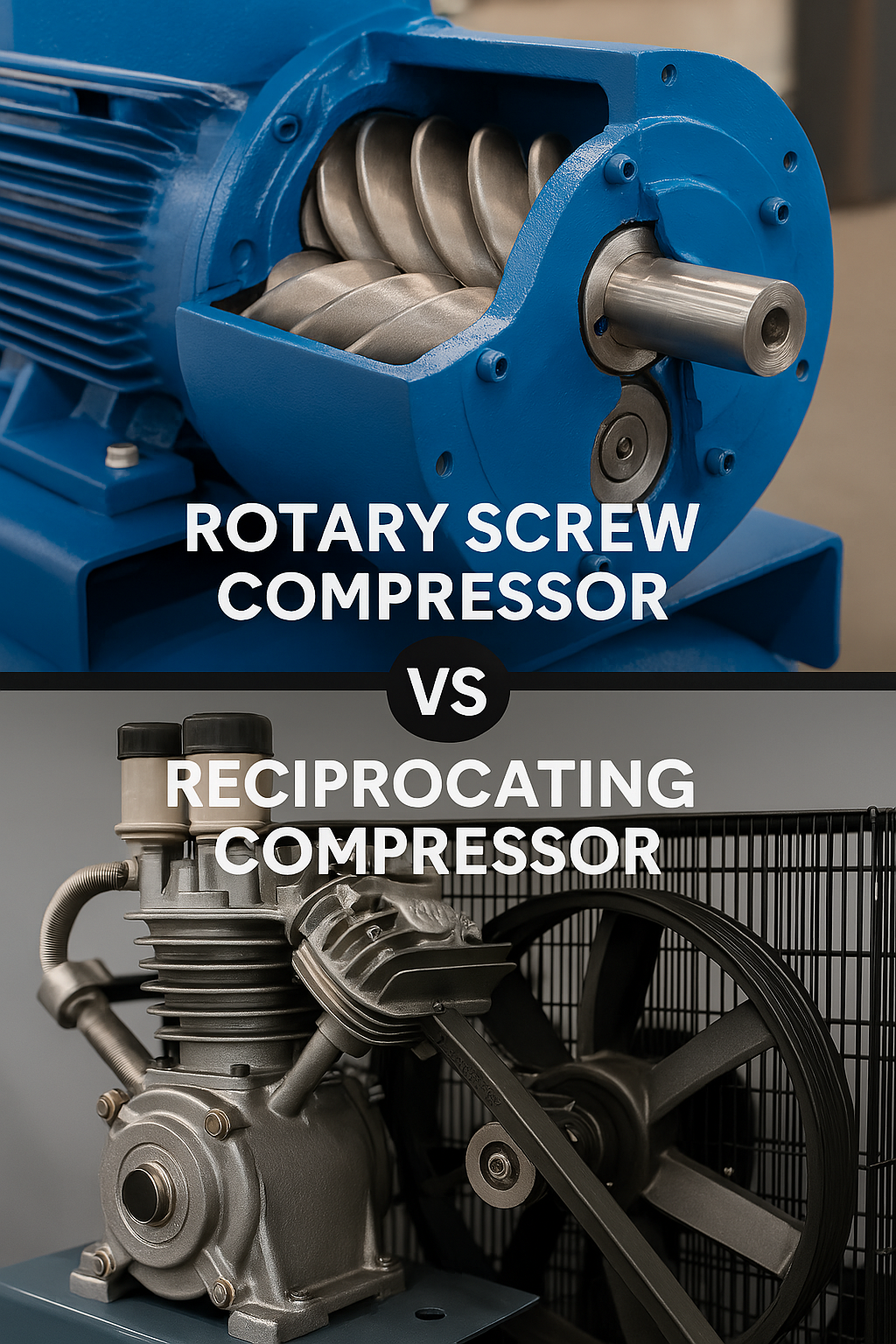

Rotary Screw Compressors: Efficiency and Reliability for Your Industrial Needs

At Power Trade X, we understand the critical role air compressors play in various industries. Among the most reliable and efficient options available are rotary screw compressors. Designed to provide a continuous supply of compressed air, these machines are ideal for a wide range of industrial applications.